Southern Highlands - Construction, November 2022

November was another busy month of work on Southern Highlands, with a large portion of time concentrating on the The Maltings, a large brick structure north of Mittagong station that at one point in time provided the prepared ingredients for making beer to all the breweries in the state of New South Wales.

As the Maltings Malthouses 1 & 2 adjacent to the Main South railway line are such a long structure, it was decided to break the construction into three main sections - two end wings, with a third main section in the centre. Each section was then broken into sub-sections to enable 3D printing of the walls and to aid in scratchbuilding the roof afterwards. Foam core board is used as the shell for the structure. Much time has been spent analysing drawings, historical and site photos, counting bricks, and designing the Malthouses 1 & 2 in a Computer Aided Design (CAD) program.

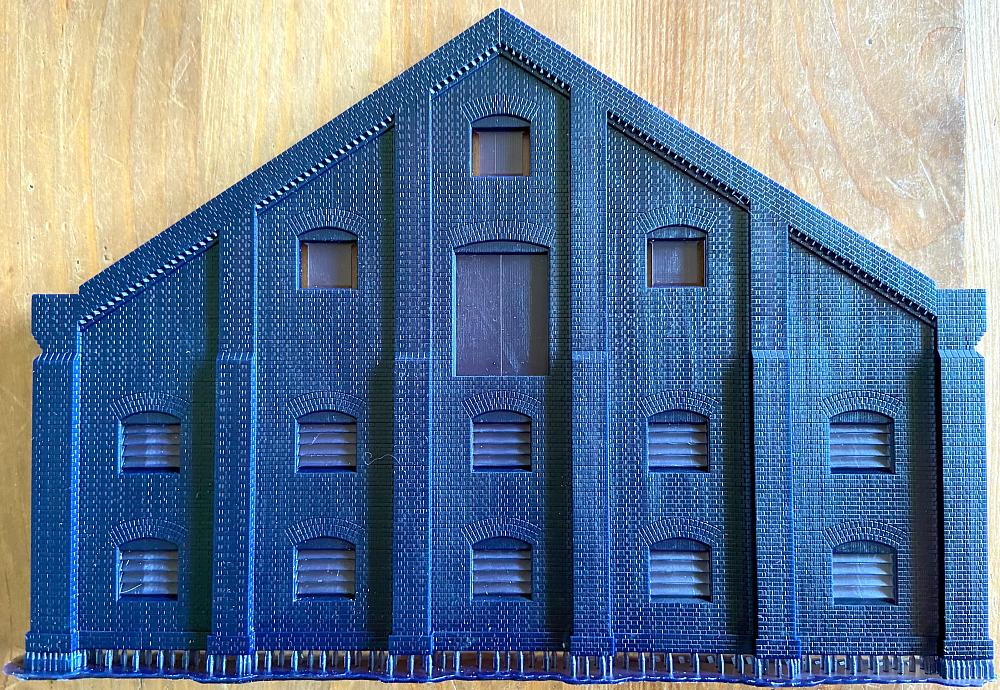

The end wall of The Mittagong Maltings Number 2 building as seen from the perimeter of the complex.

A 3D printed version of the end walls based off current and historical photos.

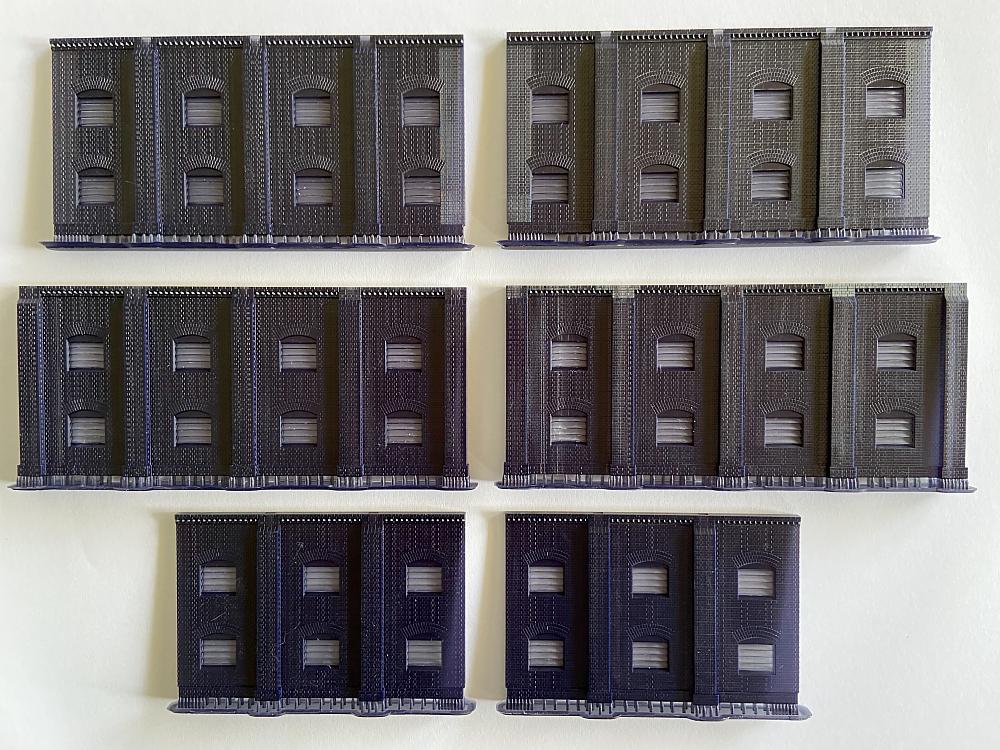

In order to fit onto the bed of a 3D printer, the end wing walls were broken into 3 sections. Two sets of walls have been printed ready for assembly.

The end wings assemblies were tackled first. The walls were glued together and to a length of foam core board. The board was then then reinforced with lengths of aluminium angle to act as stiffeners and to prevent warping of the prints.

One of the end wing walls assembled. The foamcore board shell and aluminium bracing can be clearly seen. Corner bracing in the form of foamcore board gussets have been glued into position, to keep the building square and true.

The centre section of Malthouses 1 & 2 consists of two small rooms which sit either end of a long loading dock. The rooms and wall behind were printed as one piece. The walls between these two rooms feature three different facade designs and so were drawn and printed as three pieces to be glued together.

The two small rooms and walls located either side of the loading dock.

The three distinct facades which make up part of the main section of the structure. Glazed window openings have been printed with blanks to act as supports.

A similar process was used to construct the main section. The walls were glued together and to foamcore board before being braced with aluminium and corner gussets. As the rear wall sits next to the backdrop and will not be seen, pieces of 4mm thick hardboard and 9mm ply were cut to shape and glued to the front and side walls to complete the shell. The middle of the building is taller than the rest, so the visible sections of the side walls were printed to match the rest of the facade and glued into place. More interior bracing with foam core board helps keep the shell rigid.

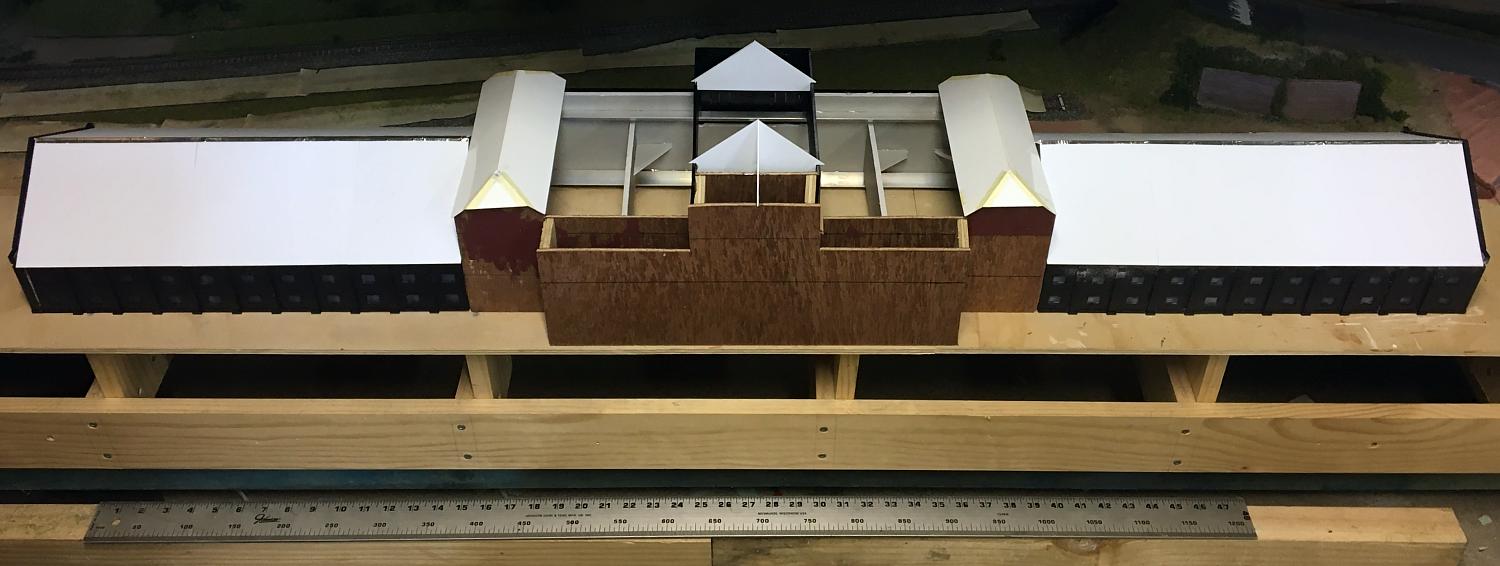

The centre section of the building, with roofing underway. A 30cm (12") steel rule sits in front.

On the end wings, a length of aluminium angle was glued along the apex of the roof to support roof. The roof was made from sheet styrene with another corrugated iron shaped styrene sheet laminated on top. The centre section has different shaped roof sections so styrene formers and bracing were cut to suit, with the same sheeting applied on top. Strips of self-adhesive aluminium tape make up the flashing.

The three sections of the maltings mocked up in approximate position on the layout. A metre rule laid in front gives an idea of the overall size of the building.

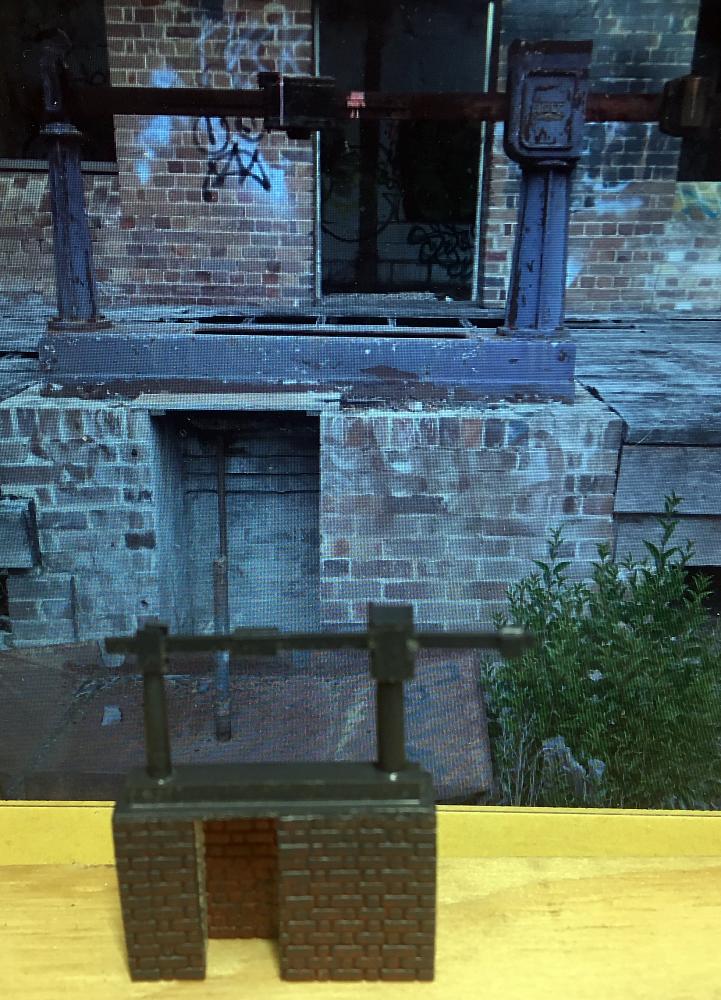

A weighbridge at the loading dock railway siding measured goods amounts coming into and out of the Maltings. The set of Asco scales and support structure have been scratchbuilt from strip styrene and brick sheet, which sit here in front of a photo of the real thing.

Other areas of the layout received attention over the course of November. The stonework of Stonequarry Creek Viaduct received varying washes of weathering before the scenery surrounding it was applied.

Stonequarry Creek Viaduct after being weathered and with various shades of base scenery being applied all around. The river bed has been sealed with Sculpt-It modelling mix and coated with acrylic paints.

The end corner of the layout with old wooden post and rail fencing near the railway line.

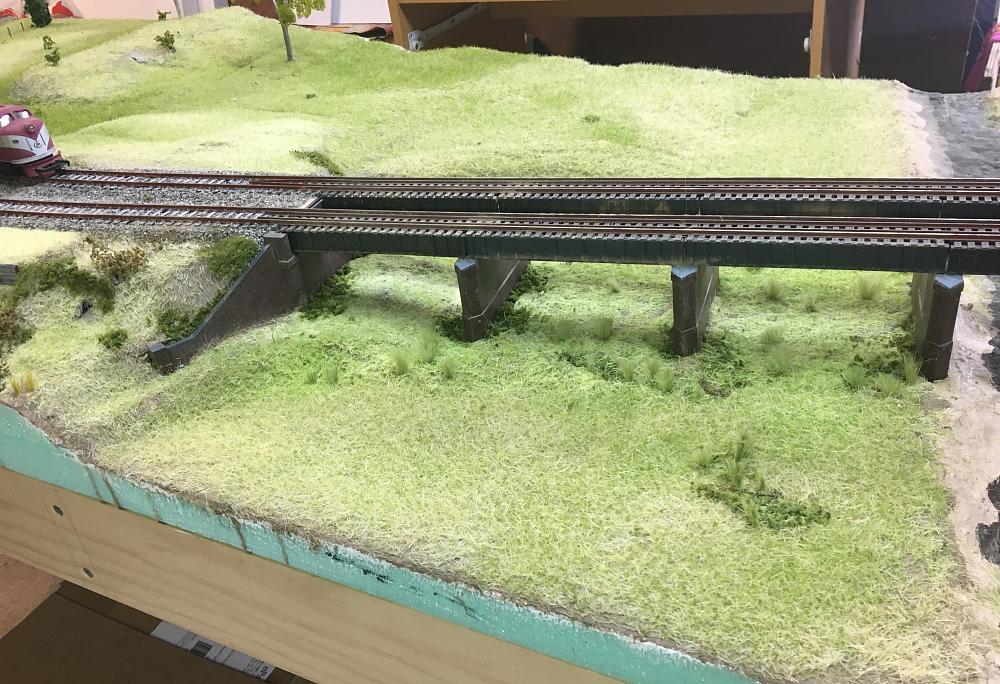

The low lying area immediately south of the Wingecarribee River featuring grassy fields behind and slightly undulating terrain.

Sometimes it is helpful to position a train or two to get an idea of how the scenery is progressing and to see how it will all fit together.

The small details that make up scenes on a layout were not forgotten. Items for placement on various parts of the layout at a later date were prepared in readiness.

Rolling stock did not miss out on detailing. An InFront Models S truck pipe load has been given a coat of light gunmetal grey paint before the straps and timbers were picked out with other colours.

Flowers for the station platforms have been painted yellow and red, ready for 'planting' in pots.

No layout is complete without people or animals. Ducks have been painted and will appear close to water sources. The 5 cent piece in the picture is 19.41 millimetres (3/4") in diameter.

Rabbits have also been painted and are ready to munch on some scale grass.

A wombat ambles away from its burrow near the Wingecarribee River.